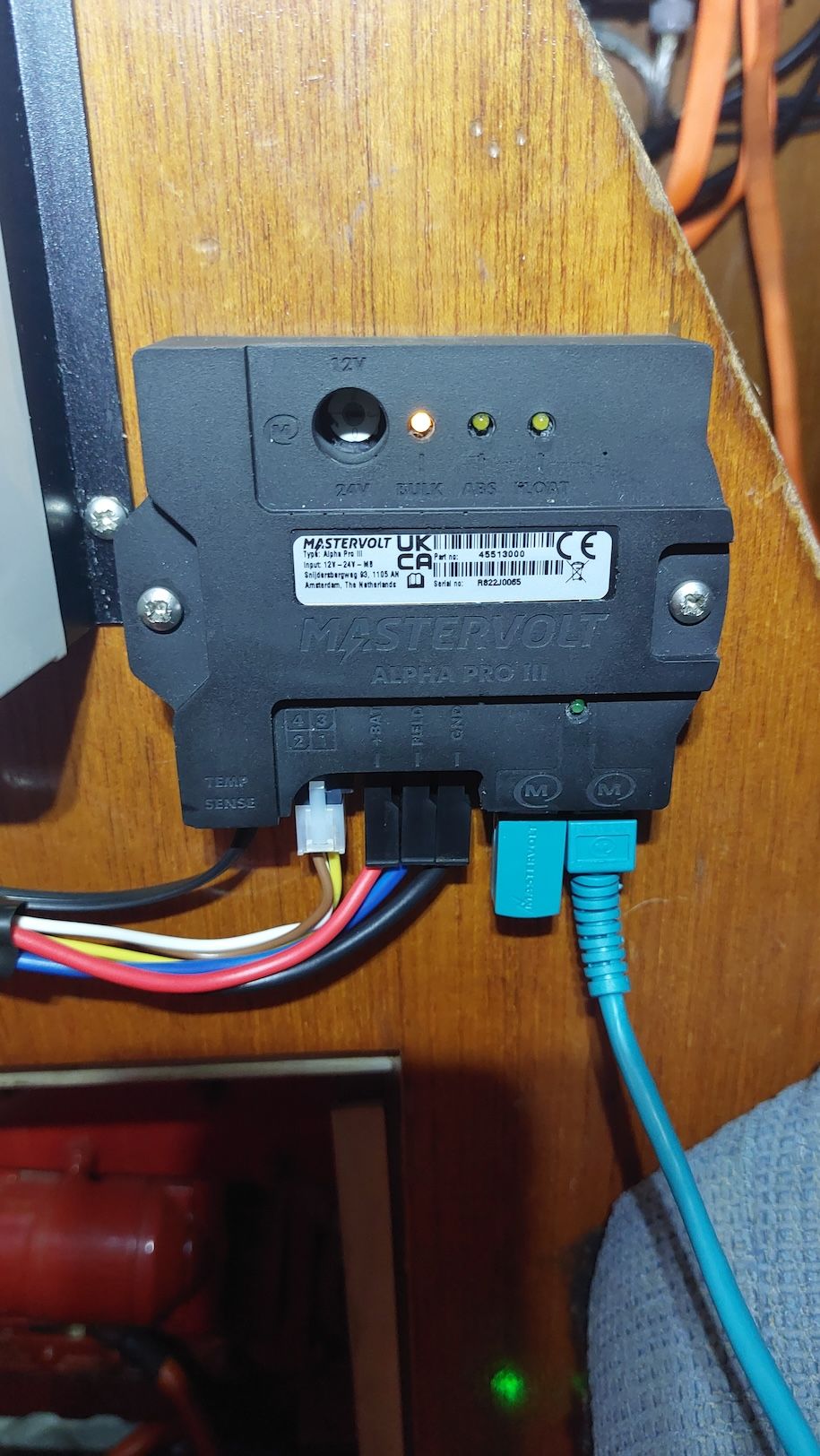

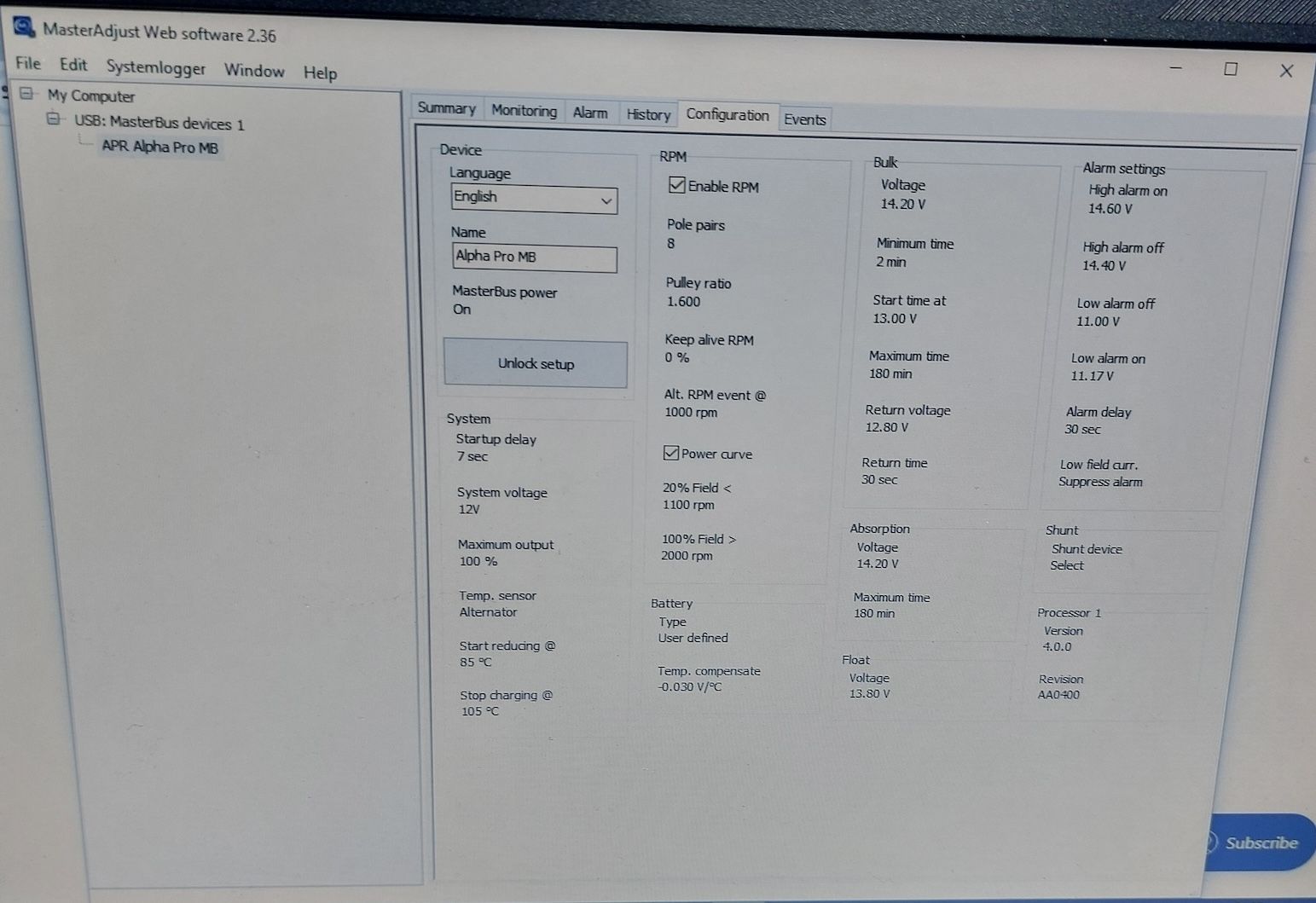

I have been postponing my knowledge on how alternators work for ages now and been using inefficient DC-DC converters to charge Lithium batteries. But finally the time has come and after some deeper research I bought Mastervolt Alpha Pro III Charge Regulator (which apparently is the most customisable in the market) despite it's need to have additional equipment to connect to Windows computer (only) and an additional terminal to monitor alternator temperatures.

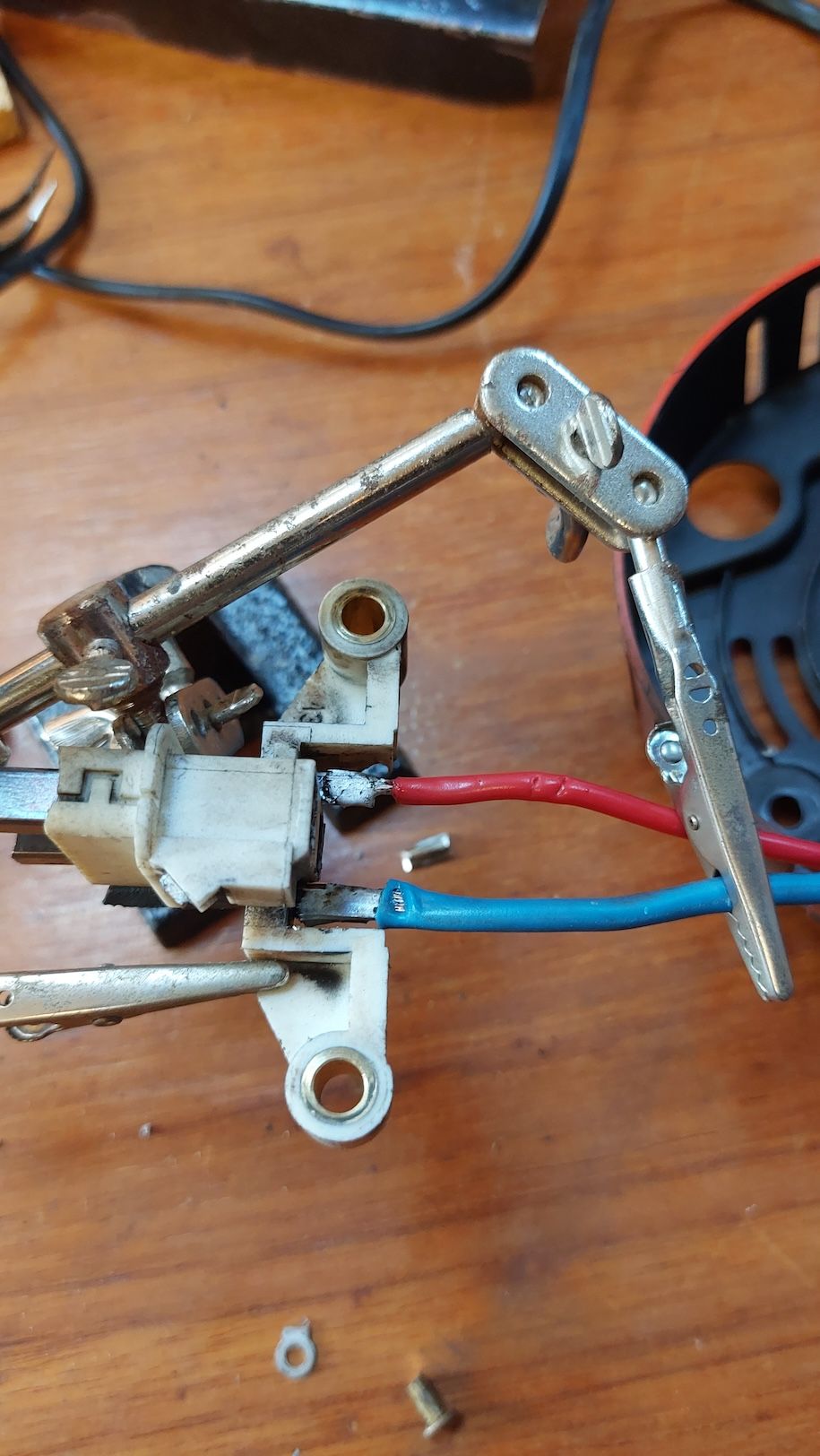

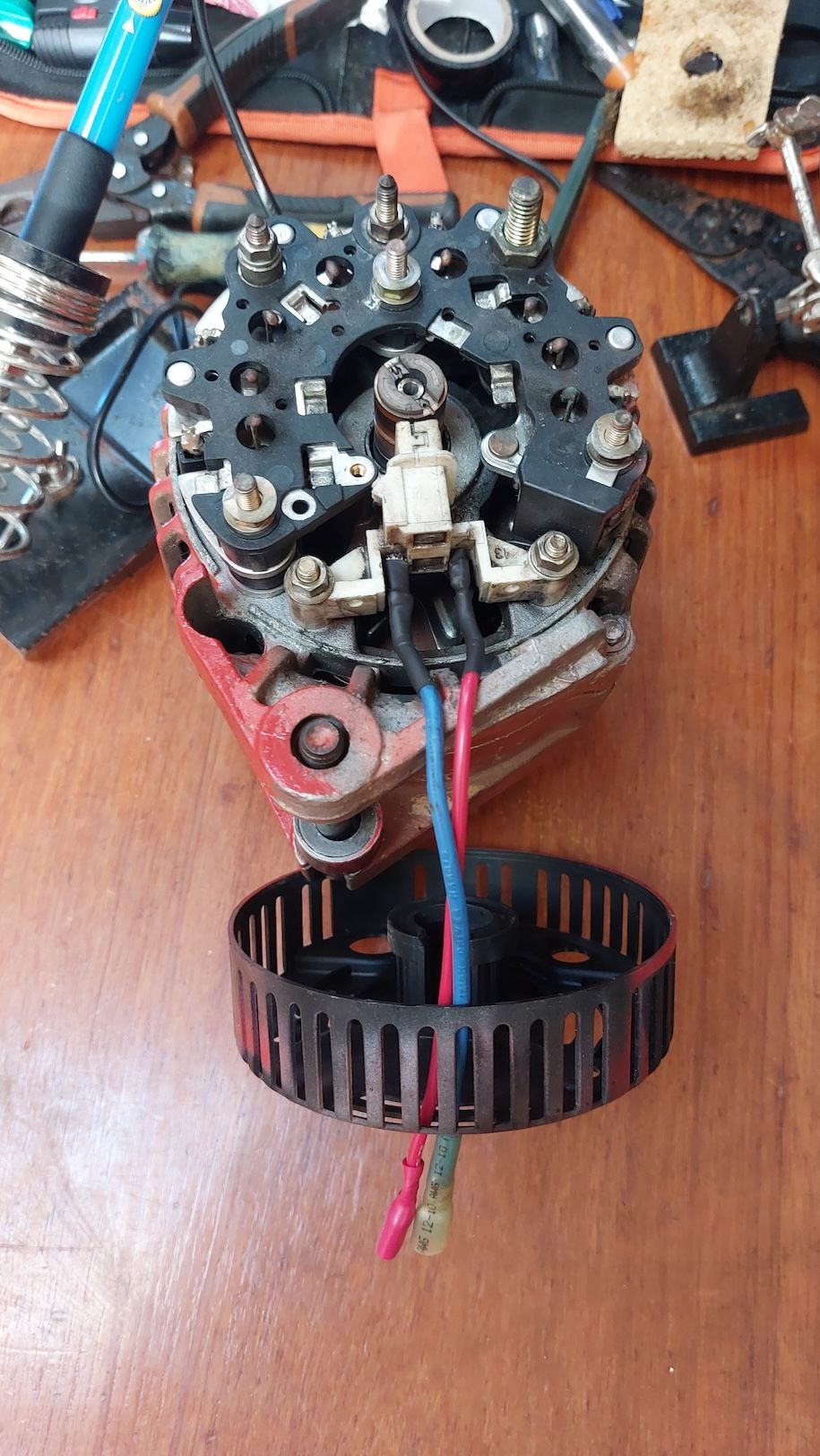

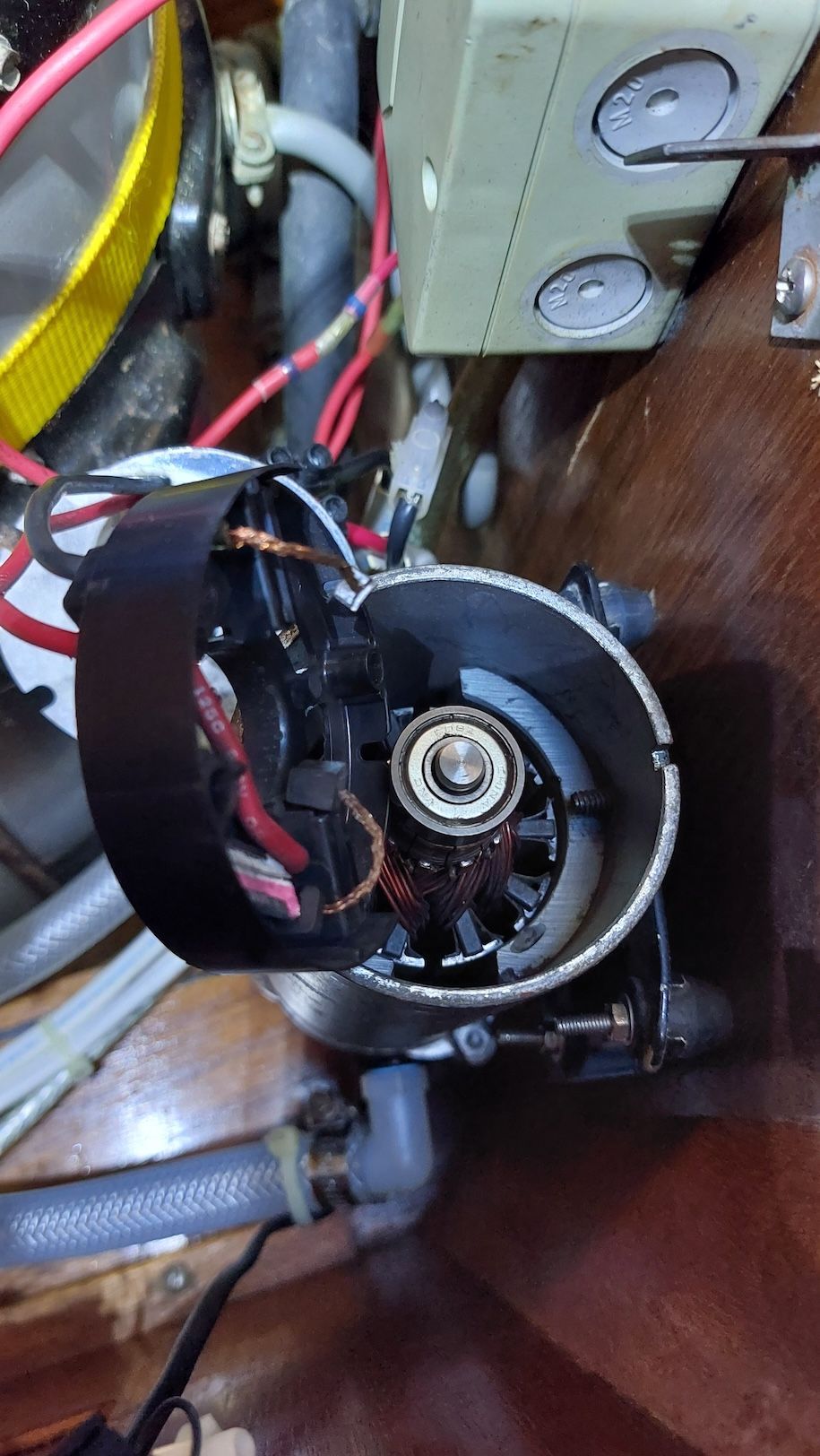

The issue was though that it needs a field sensing to control output of alternator and with the basic one I got, there was no external connections to do that. No one (engine manufacturer, nor alternator sellers and plenty of no replies after all) were able to provide information what can be done except Ed on Four Counties Marine Services after my naive email to him. Thank you so much for your advice and instructions! After a little bit of cutting and soldering, here we go :) Probably I wouldn't have been so explorious in one of the most distance locations in the world if I haven't got a spare alternator which I bought while still on Atlantic side.

Can't be happier of another toy - HIKMICRO E01 thermal camera, which I also use now to measure milk temperatures before pouring in a yogurt bacteria :)

Next stop - watermaker.

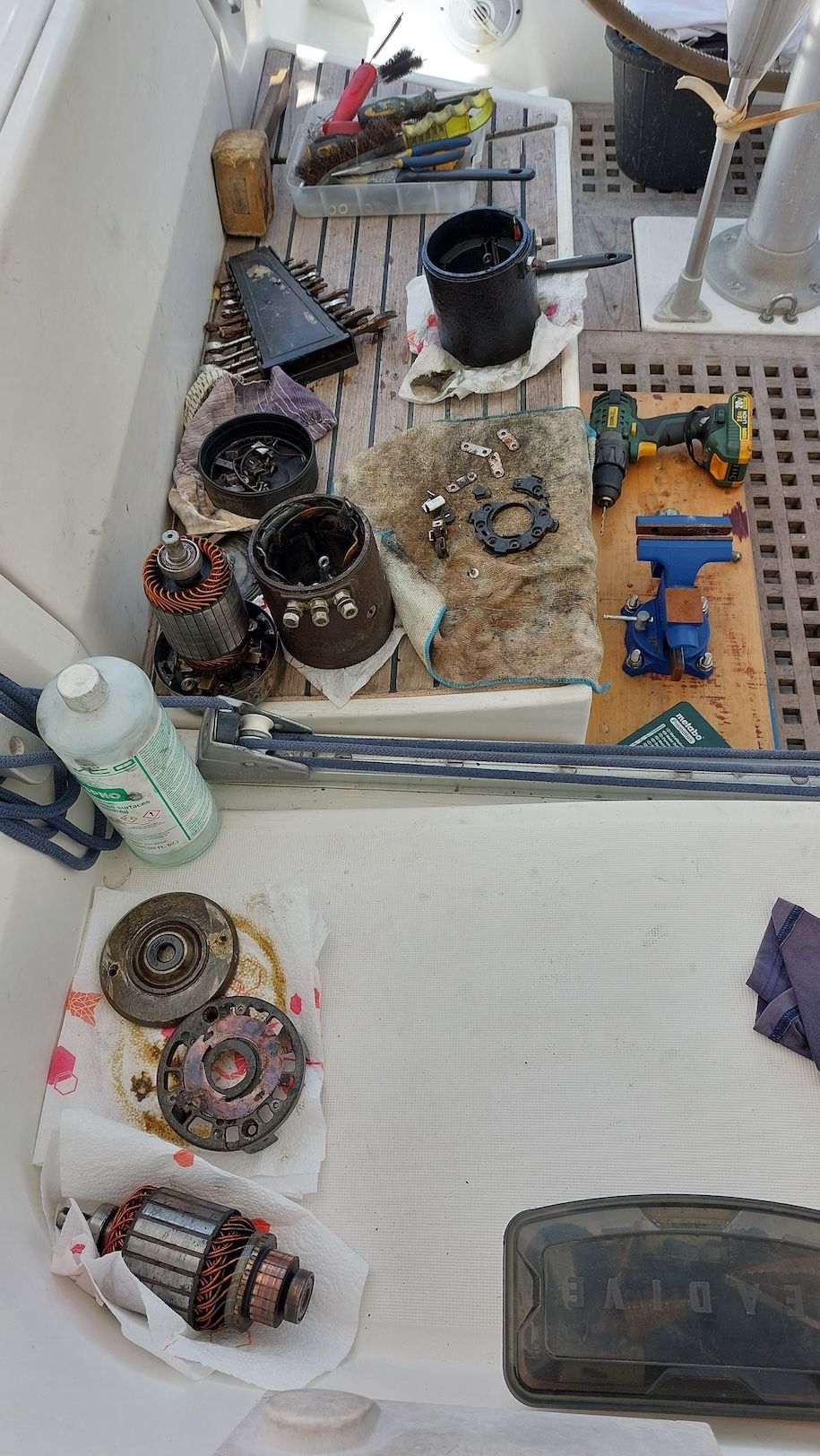

Eventually gave up on asymmetry of Spectra's clark pump as no service providers were able to resolve it and gradually water quality was decreasing that I got worried about my health. But after replacing it - another issues arose and a feed pump started to struggle. Replaced original cables and connectors to thicker ones as thermal imaging showed that pressure sensor is overheating. And most important one was to open the feed pump motor to clean the brushes as it gets dirty over the years... Negative brush is now half the size of the positive one and emits more heat but hopefully it will last until I will get to a place where it will be cheaper to get a new one (or someone will visit me and will bring a fresh one).

Last one - windless motors.

After deciding to upgrade the chain before entering the Pacific from 10mm-40m chain to lighter but nearly the same strength 8mm-90m with deeper anchor locker, it was time for a new Lofrans Kobra (only that one would fit) with new gypsy and a motor as it would struggle from time to time. Guess what - the new one was even worse!

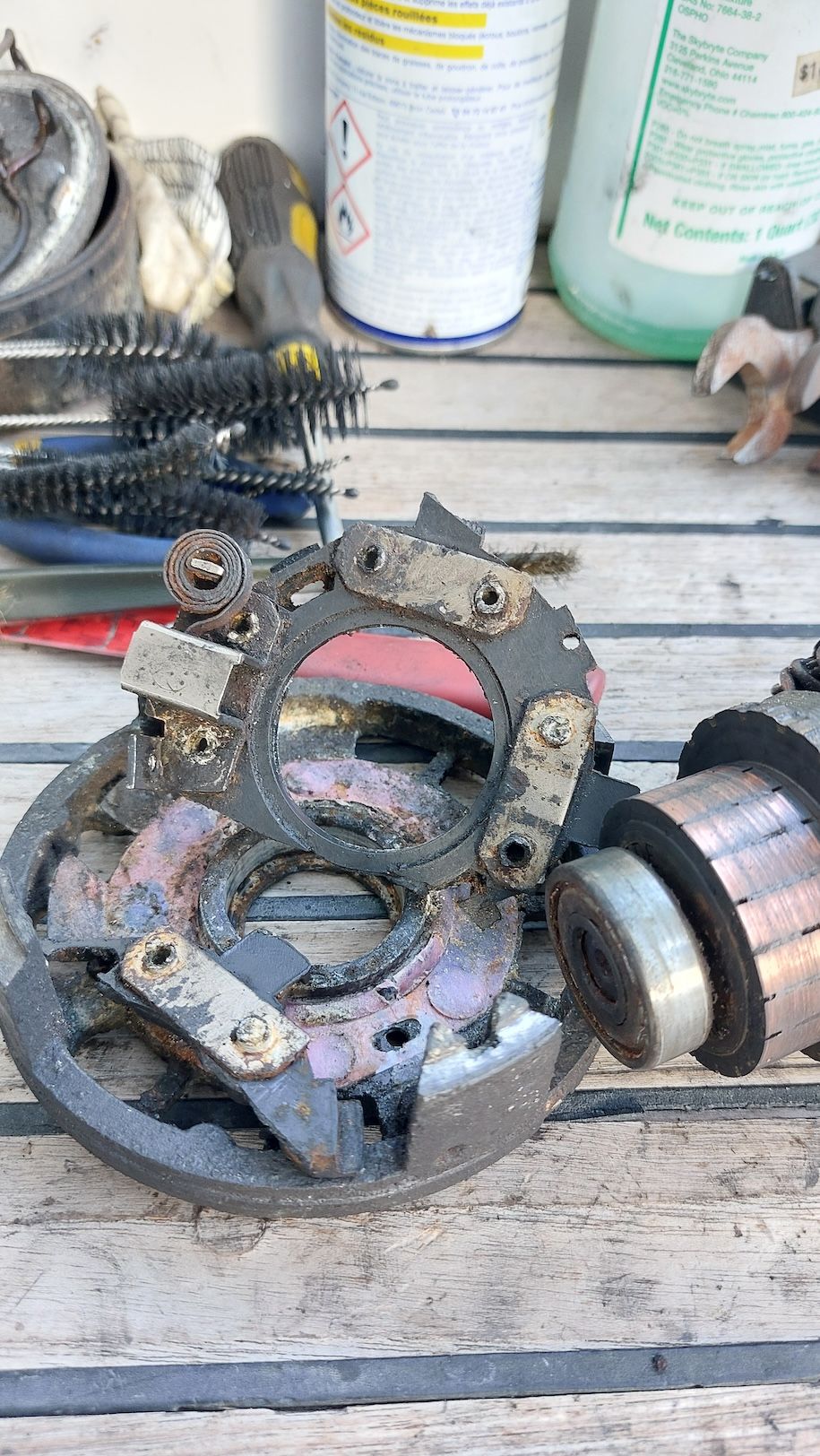

Corrosion after first time it started to hassle. Not to mention that every bolt that could seize - got seized. Bravo Lofrans!

Plastic base cracked, cheap metal (probably zinc) rivets are gone. So much rust and dirt...

So happy I decided not to throw away the old motor as it was made way better than the new one and at first I thought I will make one from two but after some careful planning and a lot cleaning, gluing, drilling, grinding, treating and greasing I was able to salvage both items.

We will see how long it will last this time. Knowledge is power but not to the point where you have to verify everything and to be disappointed how badly things are made these days...